Table of Content

In addition, manufactured home builders have earned a reputation for being early adopters of energy-efficiency initiatives and infused technology. Think hard-wired smoke detectors, smart thermostats, and doorbell cameras. The increase in average size of mobile homes has also made this increasingly possible. They are less attractive and also come under more strain from the elements. For this reason, many owners resort to installing pitched roofs on top of their flat roofs or by replacing them. Skirting is basically panels that run along the perimeter at the bottom of the mobile home and covers the open space between the home and the earth.

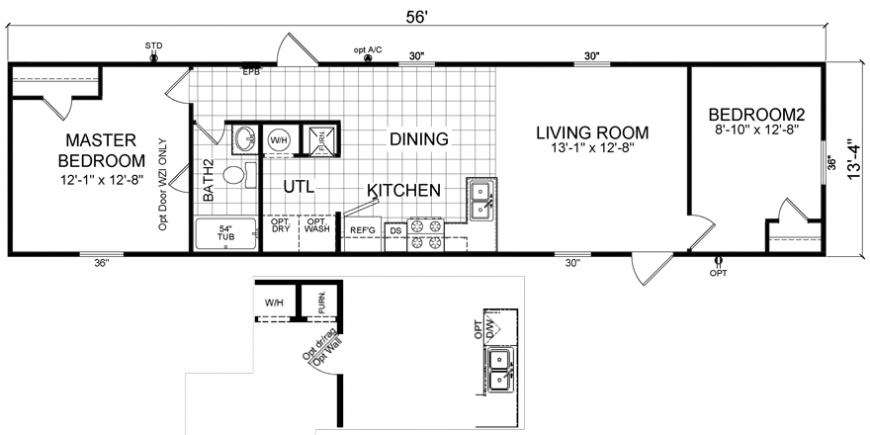

Back in the old days, mobile homes used to have 1″×2″ studs, which was not ideal for tiles. Newer manufactured homes with 2″×4″ framing can handle modern lightweight tile if installed correctly. Ceramic tile and porcelain tile are preferred over stone tile for mobile homes that can get quite heavy. Cathedral ceilings and plush carpet give this home that special bit of pizzazz. The kitchen is spread out to about 26 feet, with a wide opening into the living room.

Floor Coverings

Ceilings are usually built just like floors, only they may be constructed of lighter materials because they’re not intended to carry the same loads. On average, for a single-wide home, i.e. the floor plan with one long section usually costs $400-$550. While the mobile homes have come a long way from the initial RV phase, the design is till date not fool-proof and problems with flooring haven’t been done away with completely. However, the recent makes have started using oriented strand board to make the sub-layer and have received better feedback in terms of being water-resistant. Sub-floor is the solid flat structure just beneath the actual floor resting on the joists that provides the first line of protection from anything entering from beneath. Be it animals, floor water or mould, sub-floor acts as the barrier and prevents the floor covering from any immediate damage.

The home is securely attached to ground anchors, and reinforced with steel straps to ensure long-term stability and prevent shifting from high wind and other forces of nature. Mobile home walls are constructed much like the floors. They consist of a framework, usually in H-shapes, of wooden joists and supports.

Right Under Your Toes: Manufactured Home Floors

Particle board used in older manufactured homes is more susceptible to weakening from wetness than products like plywood and OSB, but all of them are eventually damaged by high moisture. The solution, of course, is to cut out and replace the bad areas after fixing the cause of the problem. The repair piece should go across at least two floor joist bays. In a mobile home, insulation is found in the attic, outer walls and under the floor. The under-floor insulation is held in by what is known as the “belly wrap”. Insulation standards pretty much mirror those for site-built homes with R-30 or higher in the ceilings, R-13 in the walls.

The spacing is primarily dependent on the final structure and the weight it is about to bear. Unlike on-site homes, the market for these factory-crafted modular homes are increasing, and with other players entering, and the competition is only getting tougher. The increased competition is allowing buyers to pick from a variety of choices which are increasingly more advanced. The concept came from residential caravans back in the 1960s and is a practical and comparatively much more economical approach towards housing. Unlike on-site houses, which usually take close to a year in construction, these mobile houses are a product of practicality and urban modernization. The North Carolina Board of Transportation allowed 14-foot-wide homes on the state's roads, but until January 1997, 16-foot-wide homes were not allowed.

Average Cost of a Manufactured Home in 2022

One of the great things about owning a mobile home is that there are many things that a typical DIY oriented individual can do. Most everything is more easily accessed in a mobile home; especially the plumbing underneath. Repair any damage skirting quickly to prevent problems that can occur with animals and the elements. Repair any missing insulation and belly-wrap underneath the home. This can be done by taking new plastic sheeting and spreading it over a much larger area than the damaged part.

When I walk carefully around on it, it seems to only have trusses about four feet apart. If I could find out how its put together I can figure out how to proceed. We are moving into a 76 by 16 single wide mobile home.

While a simple hardwood or laminated floor doesn’t require a long list of things, but in case one is opting for an elaborate ceramic or stick-vinyl tiles, it is better to hire a professional. Below is the list of materials required for a basic hardwood flooring. The thickness and material of sub-floor vary again depending upon the final structure and weight capacity. In older used mobile homes, a sub-layer was usually made of particle board or medium-density fibreboard. Additionally, modern homes tend to be built from materials similar to those used in site-built homes rather than inferior, lighter-weight materials. They are also more likely to physically resemble site-built homes.

Compared to the weight of book cases, aquariums, water beds, pianos and other things people move into mobile homes your guests total weight is small. If you do decide to cut an opening into the ceiling of a closet or other hidden space I would suggest attaching a strong cord to the trap. Snap traps sometimes catch a mouse or other animal as they walk by and don’t kill immediately. They can pull the trap a long way before they stop moving. With a cord attached you can pull the trap out and avoid a week or two of really unpleasant aroma. That said, they don’t like to waste money running more wire than necessary.

Every manufactured home has a chassis, or steel sub-floor frame. The beams and connecting “cross members”, as well as outriggers, of the chassis are welded steel. If you ever consider redoing the floor covering in your mobile home, it’s important to consider what materials you put down as an underlayment.

Thus, making for a big open spacious entertaining area of your home. A straightforward but practical layout, The Marvel gives you four bedrooms, a kitchen, den, living room, utility room, and two bathrooms. One or two of those bedrooms can easily turn into a welcoming office for those who work at home. Excitingly, many factories give you the power to do things your way.

For making a robust and reliable floor for the mobile home, the general schematic remains more or less the same. The initial lining is that of a floor joist, i.e. the horizontal framework spaced according to the shape and builded of the mobile home. Mobile homes are a large rectangular container type structure pre-fabricated at a manufacturing site in the form of a house. These homes are attached to a steel frame underneath with wheels, which make them easy to move from one location to another. Mobile homes are designed and constructed to be transportable by road in one or two sections.